[ad_1]

Nissan is certainly one of a number of automakers that see solid-state battery era as a possible game-changer for EVs going into the following decade. In-house, it plans to each best possible construction of all-solid-state battery (ASSB) cells and identify tips on how to lead them to, with the tech because of make it right into a manufacturing EV by means of 2028.

If all is going neatly, Nissan needs to lean at the tech so extra car sorts—particularly SUVs, pickups, and trucks—make sense in totally electrical shape by means of the tip of the last decade.

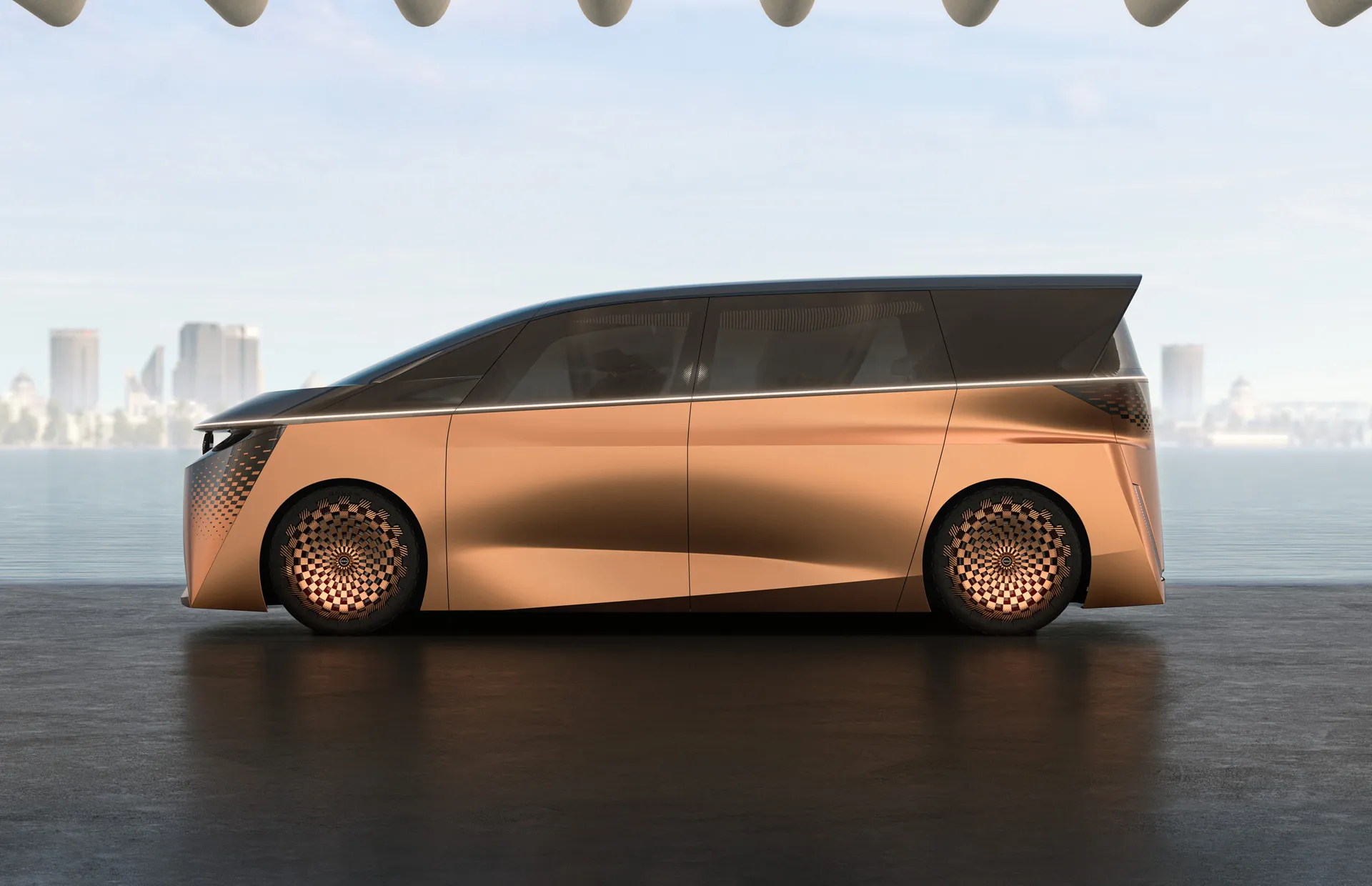

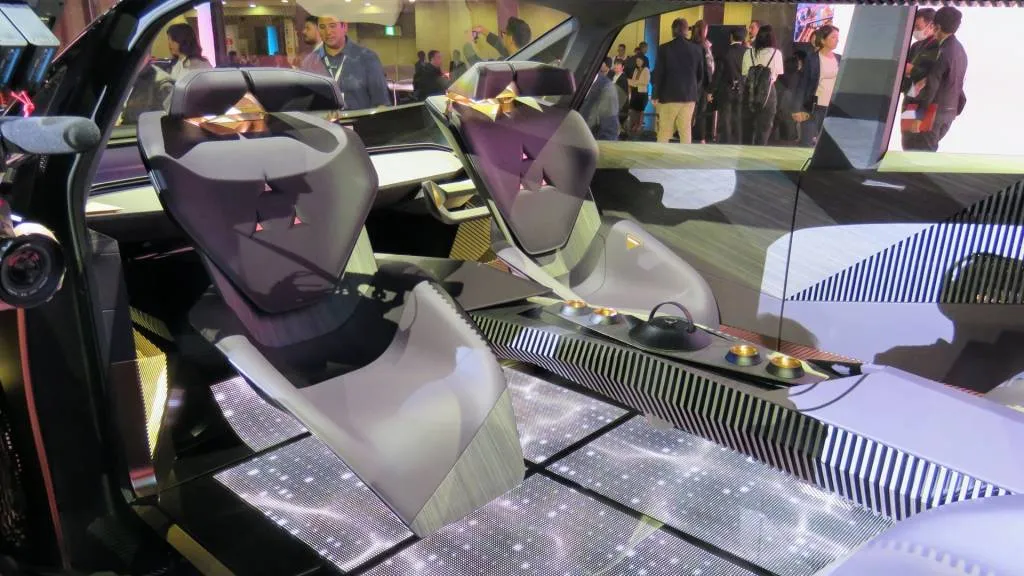

That looked to be the gist at the back of the Hyper Tourer thought Nissan displayed on the Tokyo auto display ultimate week, suggesting an overly skinny, flat solid-state battery pack under the ground, affording long-range cruising with out the packaging compromise.

Nissan Hyper Tourer thought

Nissan Hyper Tourer thought

Nissan Hyper Tourer thought

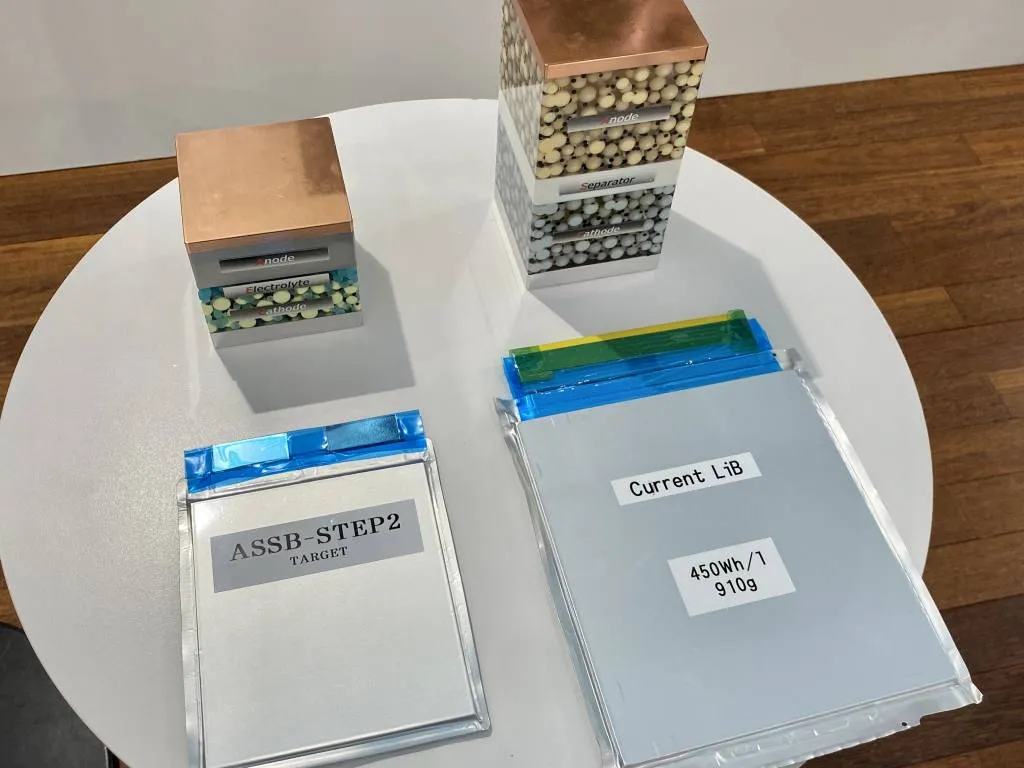

As opposed to the present lithium-ion mobile tech in EVs, Nissan is aiming to successfully double the power density on the pack degree, whilst slicing the short charging time by means of two-thirds.

On the identical time, lithium-ion chemistries and different battery sorts are evolving and making improvements to. In a roundtable interview ultimate week on the Tokyo auto display, Nissan’s international R&D leader Kazuhiro Doi informed Inexperienced Automotive Experiences that solid-state mobile tech can’t simply be an incremental development over lithium-ion.

To hit the ones objectives, Doi underscored, it’s going to preferably want to cross without a cooling in any respect.

Cast-state runs scorching and that’s OK

“With regards to ASSB, perhaps we will be able to get rid of the cooling,” he mentioned, emphasizing that it’s nonetheless now not mounted on a last design, however it’s aiming to steer clear of it fully.

As Doi showed to a couple raised eyebrows and verified to Inexperienced Automotive Experiences, that suggests no water cooling, no forced-air cooling, and now not even any passive cooling—for sure other than what some automakers have recommended.

2011 Nissan Leaf – battery pack cutaway

This can be a little bit of a loaded topic. Nissan underestimated the cooling wishes of the unique battery cells used within the Nissan Leaf, which degraded briefly in scorching climates when parked over scorching blacktop or fast-charged too incessantly. A next battery-chemistry exchange in 2015 helped clear up that, and because then Leaf battery degradation has been significantly better.

Eliminating the cumbersome water-cooling machine in different fashionable EVs has been a objective for construction engineers. Mercedes thought to be air-cooling in its contemporary EQXX thought, presaging its new technology of EVs—nonetheless with lithium-ion cells—and in the long run made up our minds in opposition to it.

However Nissan has extra hands-on revel in with the tech already, and the reason at the back of going with out cooling for ASSB is understated: It’s OK for them to get a lot warmer than what can be thought to be standard for different EV batteries, and the cells have a large temperature candy spot—from room temperature all of the method as much as 100 levels C or 212 levels F.

To deal with the merit over lithium-ion chemistries and make all of the construction profitable, Nissan will want to have a awesome product by means of then that wouldn’t be depending on cooling, Doi once more emphasised.

For many lithium-ion cells, the temperature threshold is set 60 C or 140 F, and immediate charging instances are restricted to stop mobile temperatures from coming near that temperature. With out being concerned such a lot about temperature, Nissan’s solid-state cells could possibly rate to close 100% in about quarter-hour.

Nissan Surf-Out, Max-Out and Grasp-Out ideas

Nissan sees solid-state going large first

Cast state might be acceptable to all kinds of cars. Whilst some corporations—Toyota, as an example—have hinted that solid-state cells would possibly first seem in hybrids. Nissan believes one form of fashion makes extra sense to take solid-state first: large, long-range, totally electrical cars.

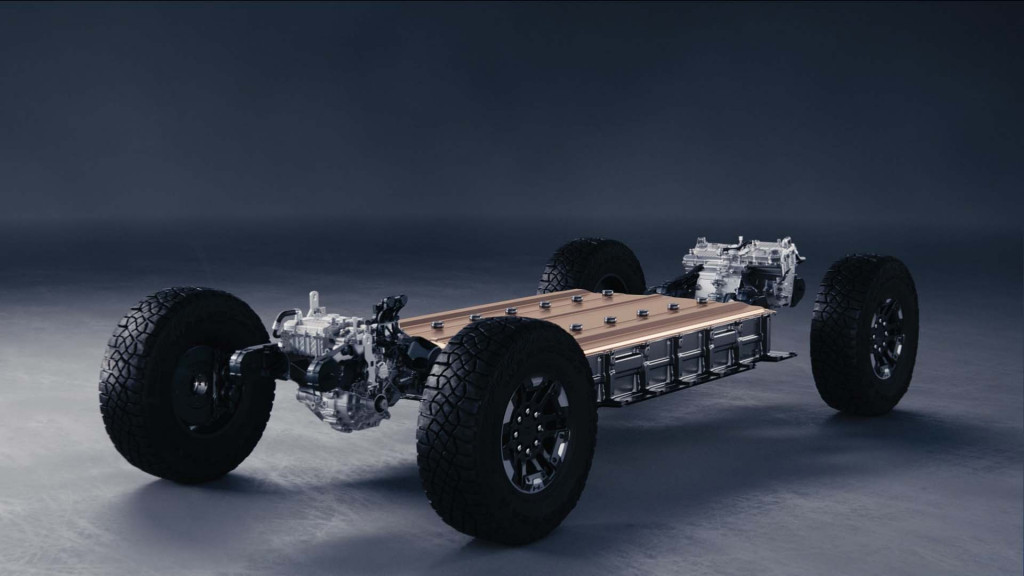

Doi defined that vans, trucks, and SUVs require a lot more power, “but when we make the most of that nowadays with lithium-ion battery tech, the scale is very large.” Slicing the cooling machine out of the equation would imply smaller packaging and some distance much less complexity for the battery pack, permitting it to liberate house for roomier cars—or, doubtlessly, for extra fluctuate and not more mass.

2022 GMC Hummer EV

Juggling continual, protection, cycle lifestyles

This time round, Nissan must get the battery composition proper from the beginning, and there are longevity hurdles but to resolve. In a laboratory state of affairs with scaled-up check cells it’s seeing round 200 cycles—now not any place close to sufficient for a manufacturing EV but.

After first operating with single-layer cells simply 2 cm throughout within the laboratory, Nissan nonetheless plans to determine a pilot line for cells about 10 cm throughout in 2024. The real manufacturing mobile can be “a lot bigger” than that, Doi mentioned. Nissan plans to make larger-format cells on the pilot facility, as it really works out the scale of the plant it would want to ramp up manufacturing.

As Doi had prior to now mentioned, Nissan is incorporating its personal nail-piercing checks and X-ray imaging into its research of the solid-state cells, which can be subjected to rigorous protection and sturdiness checking out. The Nissan Leaf has had no circumstances of fires or thermal runaway, and it’s construction those new cells with the similar protection priorities.

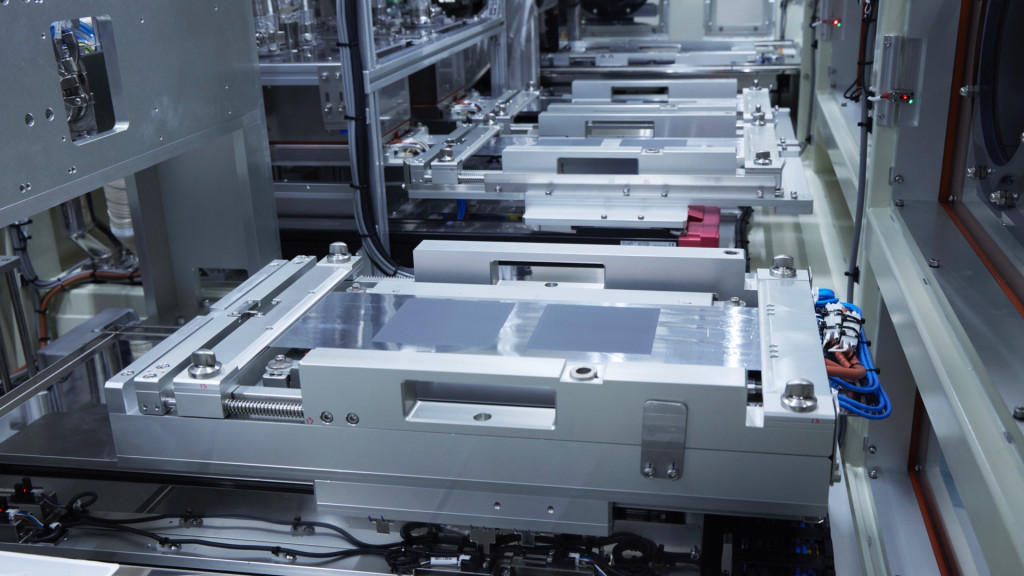

Nissan solid-state battery prototype manufacturing

Nissan’s solid-state tech advantages from a partnership with NASA and UC San Diego during which AI ways helped make a choice the most productive interlayer to stop the expansion of lithium dendrites that would possibly in the end piece via, short-circuiting the cells. The high-ion-conductive electrolyte used to be selected for balance, with the anode for high-power doable.

Nevertheless it’s now not accomplished fine-tuning the cells and isn’t ready to present specifications for them slightly but. Mobile efficiency is not just mounted by means of chemistry however by means of the cathode and anode layers, Doi defined. A thicker cathode will yield extra power density but in addition get in the way in which of rate charges. “First we want to repair the chemistry, and after we repair the chemistry we will be able to estimate the efficiency in keeping with mobile,” he mentioned.

Nissan ASSB vs lithium-ion

Cast-state tech evolution

Doi additionally emphasised that there can be numerous evolution of the chemistry. The addition of nickel for power density and fluctuate in lithium-ion cells is one instance, he mentioned, and the similar kind of factor will occur for stable state.

ASSB apart, high-manganese and sulfur-based chemistries are the following perfect hope, Doi says. “Then we will be able to make the most of that even for the small vehicles—I feel the prospective could be very horny,” he mentioned.

Nissan is focused on a value of simply $75 in keeping with kwh for solid-state cells, which would possibly put it on par with lithium-ion on the finish of the last decade. If it will possibly use ASSB for larger cars, the candy spot for smaller EVs could be in some aggregate of the ones chemistries with stable state—a fair lower-cost, less-resource-intensive answer with out the life-cycle demanding situations. Cooling for any such aggregate is but to be decided, regardless that.

[ad_2]