[ad_1]

For those who’re a very long-time Speedhunters reader – we’re speaking over a decade right here – you’ll certainly take into accout Nigel Petrie‘s Engineered To Slide Toyota Hilux. However even though you haven’t been studying for that lengthy, there’s nonetheless an excellent probability you’ll know of Nigel’s construct, as a result of there used to be not anything else find it irresistible on the time it used to be created and it’s nonetheless an epic system as of late.

Given the intensity of our archives, we concept it could be amusing to begin revisiting some earlier Speedhunters options, and the place higher to start out than the ETS Hilux, which used to be featured precisely 10 years in the past in October 2013. Shot by means of Dino in Sydney, Australia throughout the 2013 Global Time Assault Problem and written by means of Nigel himself, this tale wrapped the Hilux construct collection on Speedhunters. You’ll discover a hyperlink to the entire tales in that collection on the backside of the web page, so you’ll experience them once more or be informed for the primary time how this superb mission got here in combination.

Let’s wind the clock again to 2013…

The Tale So A long way

Excellent issues come to people who wait, or in Nigel Petrie’s case, they arrive to people who devote each and every ultimate minute in their spare time to a dream, to a imaginative and prescient of constructing one thing bespoke. We’ve come throughout some beautiful inspiring builds through the years right here at Speedhunters however the ‘Float Ute’ is not like the rest in the market. Because of Nigel preserving us up to date with the development of his construct through the years, we’ve observed this mission materialise, getting a glimpse on the quantity of labor and sheer dedication required to take an concept from one’s head, and switch it into fact. Now that the Engineered To Slide Hilux is all finished, it’s after all time to take pleasure in its main points and respect the years of labor which were poured into it. We’ll let Nigel take over from right here:

Welcome again, Speedhunters! It’s been just about 3 months because the ultimate construct replace and I’m overjoyed to deliver you the completed product. I need to provide you with some perception into what’s been taking place within the ultimate months since that first actual check pressure. Developing a automobile from not anything has its demanding situations; these types of demanding situations are extraordinarily onerous to conquer however I believe that’s the gas to my fireplace, that intense headache that simply received’t cross away till the problem is resolved, provides me the fervour to proceed. I took slightly smash after the construct used to be entire however no longer completed; by means of that I imply it used to be working, using, and aesthetically in combination however I wanted to ensure the entirety used to be able for paint and powder-coat. I began to take into accounts the chassis and the way I sought after it to be completed. Each time I wipe the tube down with thinners I like the metal’s good colors, however because the moisture of the thinners disappears so does the color. I began to take into accounts how I may harness that deep clean glance as the completed product.

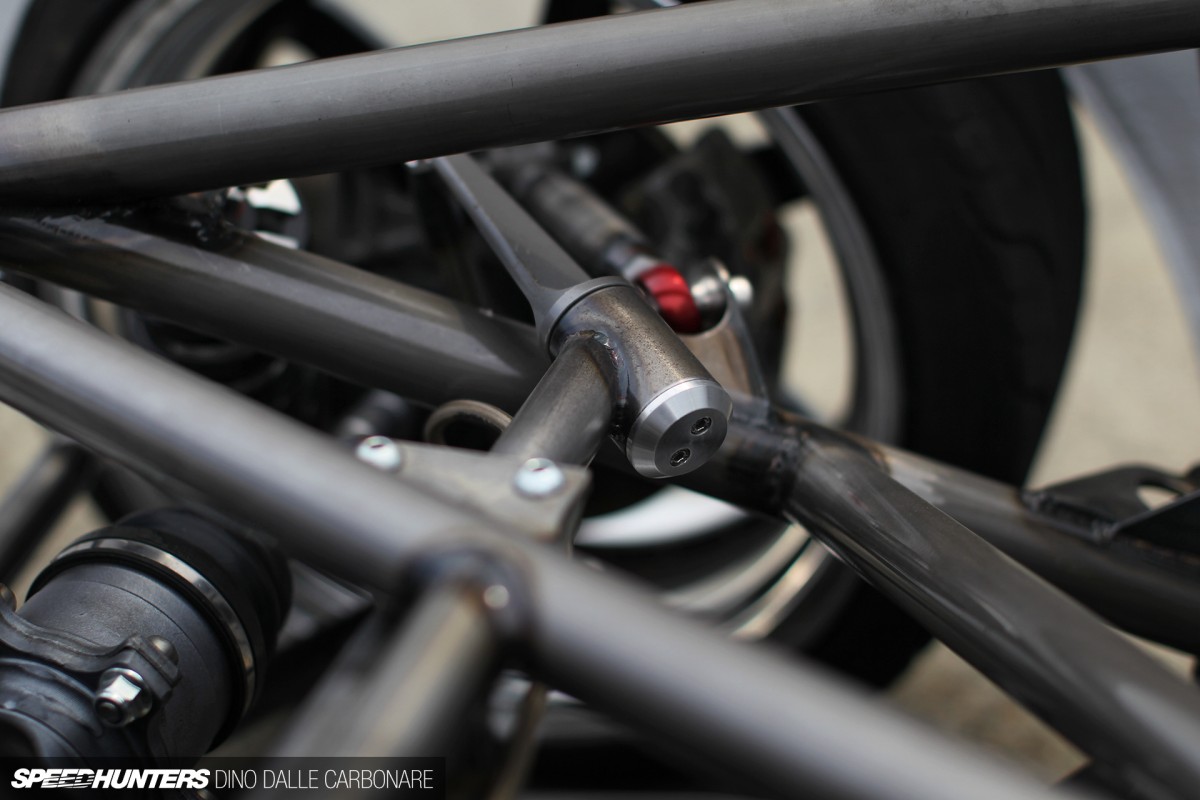

It used to be this problem that took me to Colourtech Powdercoating Geelong. Initially I requested the blokes if they’d clean powdercoat. They did however they’d reservations about how it could paintings. I made up our minds to provide it a cross and after you have house I stripped my BMX all the way down to uncooked metal and returned it to them able to coat. After I returned to select up the body, I used to be blown away: the metal had the inner most shine, the welds had probably the most stunning distinction to them and the best way the warmth marks mixed in with the metal needed to be observed to be believed. I temporarily reassembled the BMX and began checking out its sturdiness. It held up extraordinarily neatly and I used to be so happy to have a last chassis end locked in. A couple of days later I might go back to a sight I were dreaming of for 2 and a part years: earlier than me used to be the completed chassis in all its clear-coated glory. No longer handiest the chassis, however the guidance column, sprint mount, suspension palms, subframe and plenty of different hand fabricated items. The powder is electrostatically charged onto the portions permitting each and every little space to be coated.

In a while, Tim from Breakwater Panels referred to as me and stated the bodywork used to be able to select up. I used to be like a child on Christmas morning. I arrived to select up the superbly flow-coated Toyota Tremendous White frame and I couldn’t be happier. It used to be higher than I ever imagined.

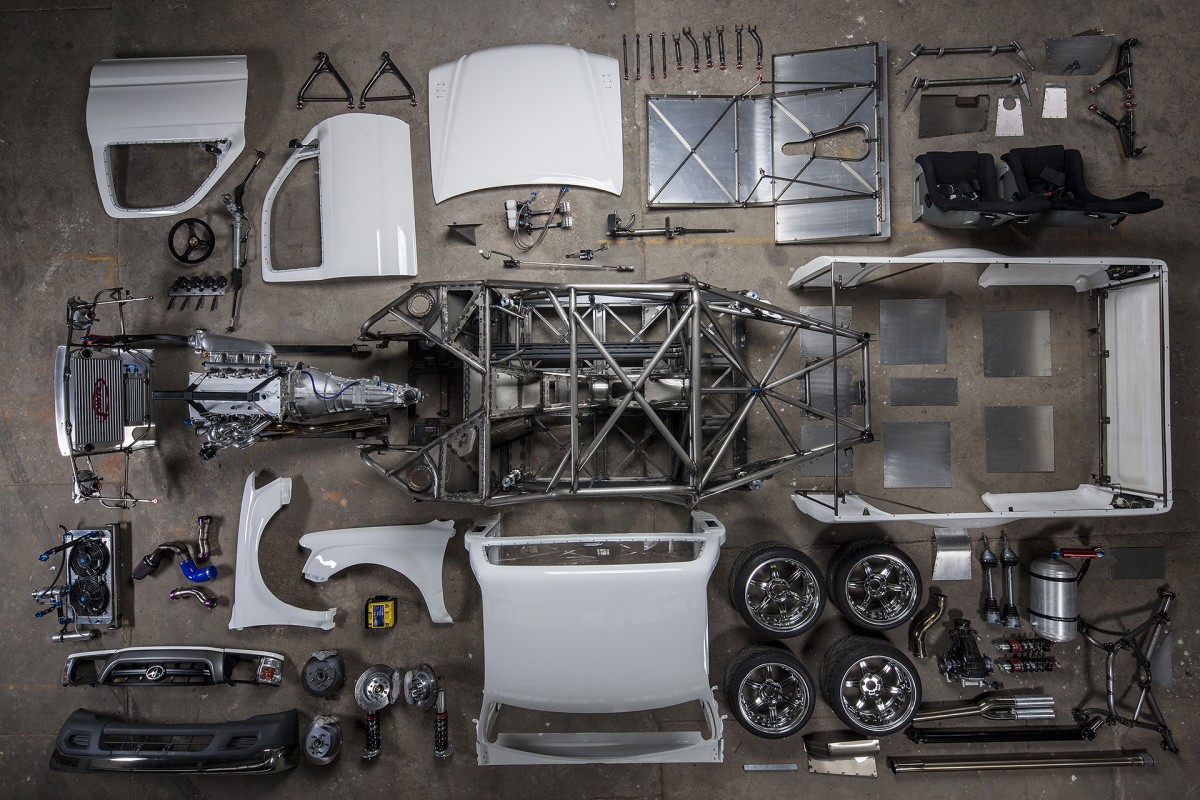

The following few nights I put in combination the sub assemblies, ensuring that the entirety used to be entire and able to head. It used to be at this level I mirrored on what I were by way of. Dealing with every section and seeing it in its completed state gave me flashbacks; the volume of effort and time long gone into every one won’t ever be understood by means of somebody however myself.

My pal Dean and I got here up with this brilliantly silly plan to gather the automobile in an deserted manufacturing unit with a roof fixed digital camera tethered to a pc and lit with some studio lighting. What’s silly about this you ask? It used to be a daft quantity of labor and to do it with out bumping every other portions used to be a nightmare. The effects had been insane even though and I will be able to’t thank Dean sufficient for his assist. After bringing the Hilux again house it used to be executed. It took a couple of nights to in reality kick in that it used to be completed. A snappy flick of the ignition and a press at the get started button showed that the electronics went again in as they will have to. I had simply constructed probably the most complicated automobile puzzle and all of it went in combination like clockwork. Let’s take slightly detailed have a look at it…

Final touch Completed

The plan from the start used to be to stay the frame as inventory as imaginable: this contains the inventory Tremendous White Toyota paint paintings.

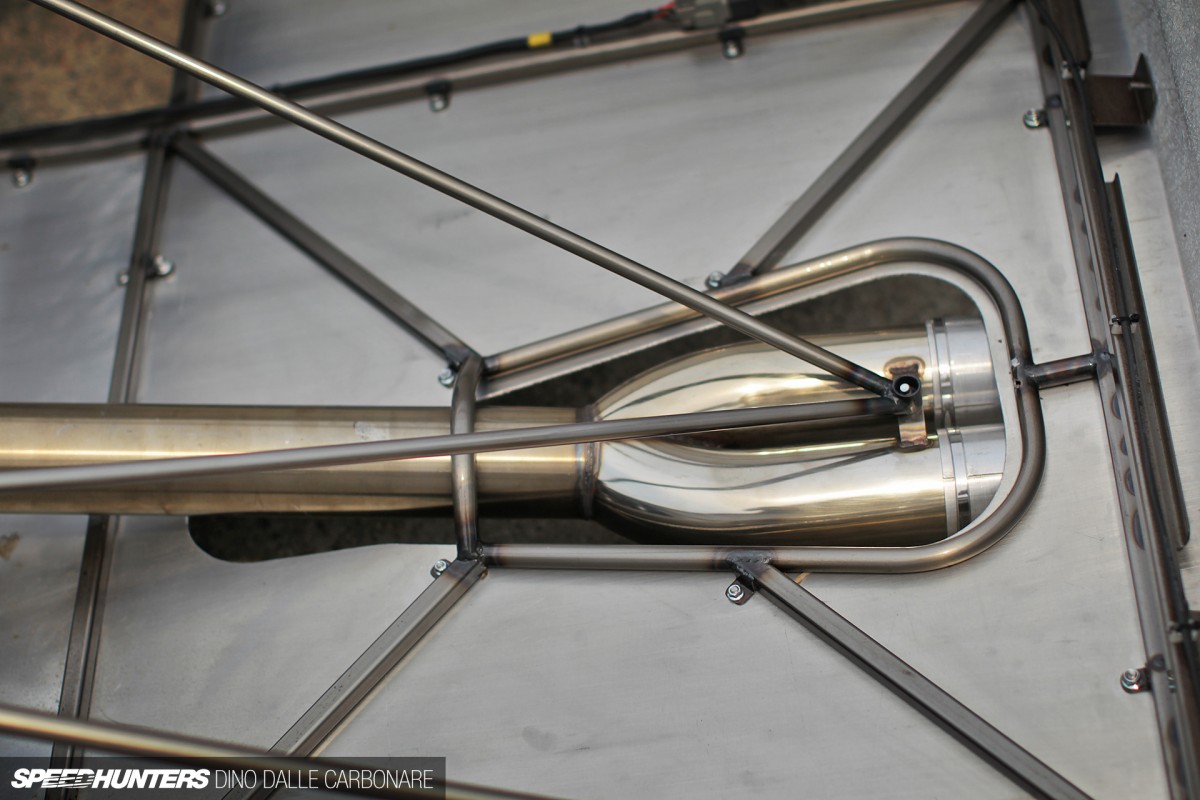

Surrounded by means of the FRP shell and alloy under-tray, the metal construction is probably the most visual and admired facet of the construct.

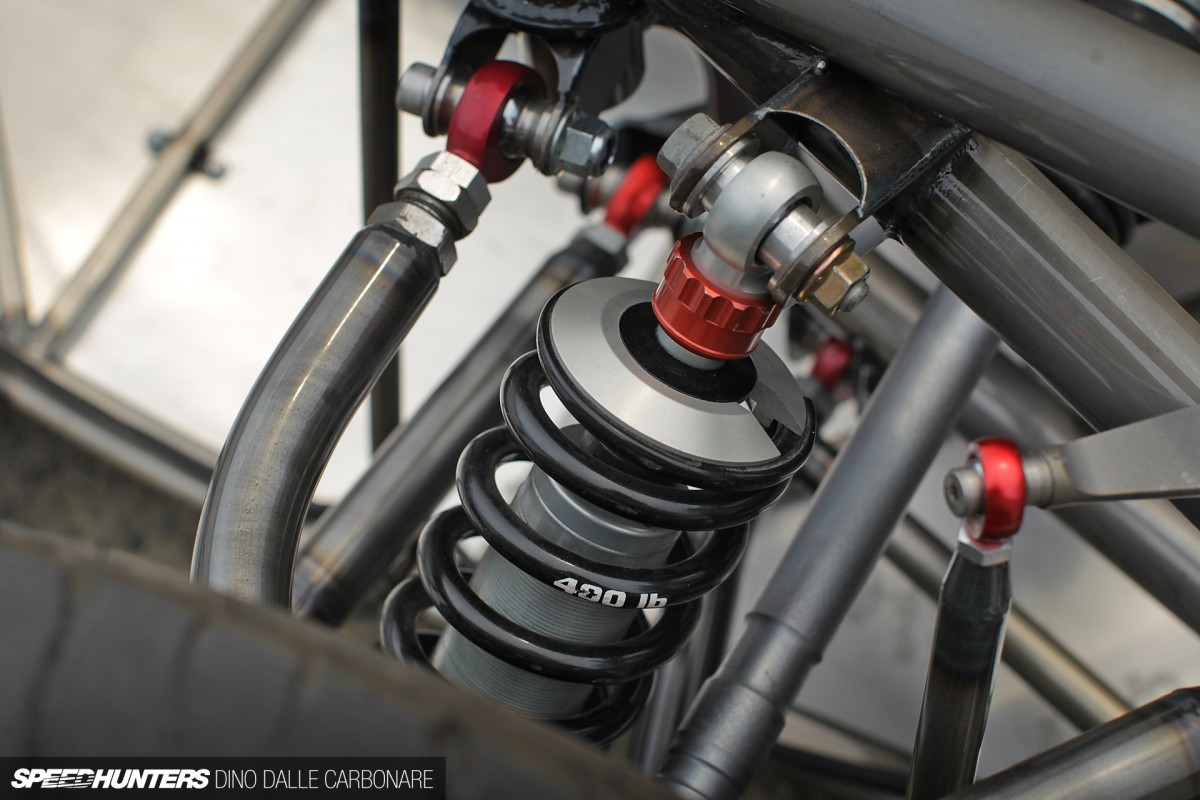

The suspension itself makes use of MCA shocks…

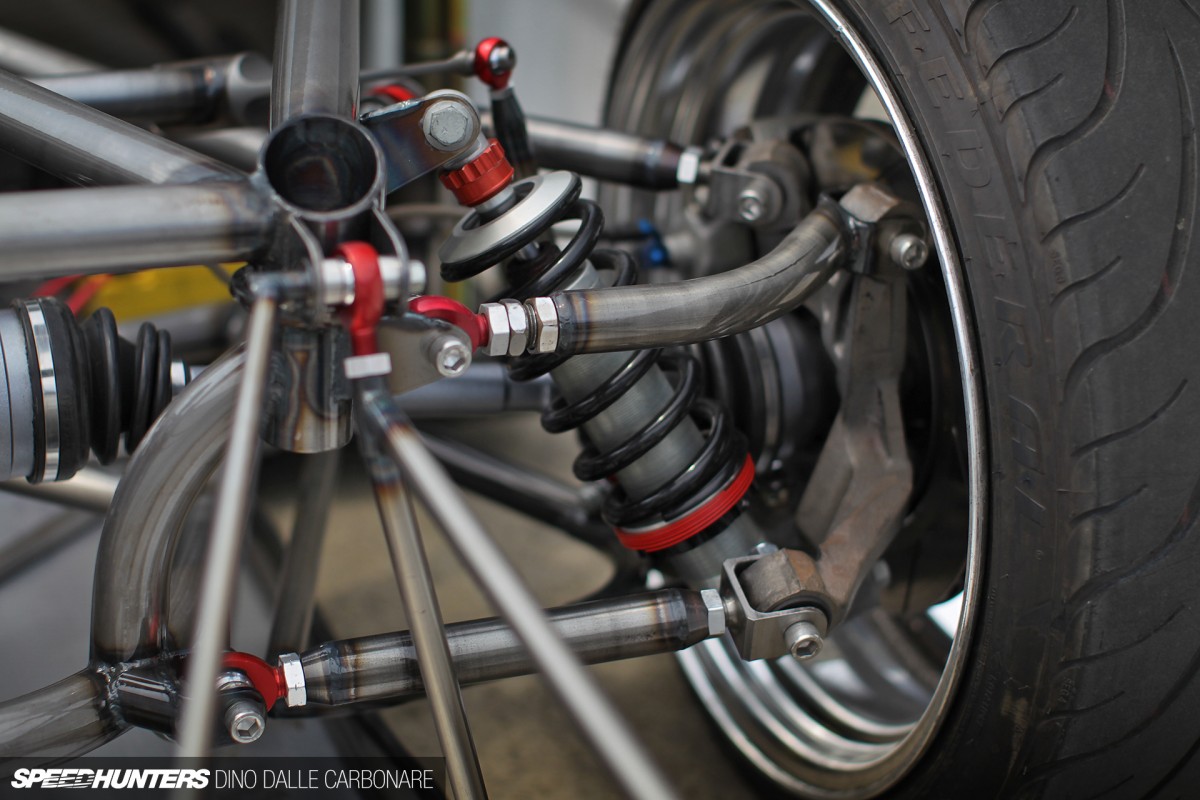

… chromoly palms and QA1 rose joints. The structure is very similar to that of a Nissan S15 multi-link rear finish.

The plan at the beginning used to be to make use of a manufacturing unit S15 cradle, however after development the chassis, this concept used to be ditched in favour of one thing better-looking. I advanced the geometry, forged fixed the diff, then made up the palms.

The rear sway bar is very similar to the entrance with V8 supercar blade adjustable ends tied along side 1.25-inch chromoly tube and brass timber. Just like the entrance, those blade ends shall be remade to a softer price to mirror the chassis weight.

The diff is an R200 with a mechanical two-way LSD inside of it. The shafts are your standard S-series five-bolts and the knuckles are S15 pieces.

Having the entire freedom on the earth with a floor up construct will provide you with many choices. When it got here time to make a choice a gas tank, I did issues slightly other and decided on a spun alloy upright tank that removes a large number of the gas surge a flat tank would have.

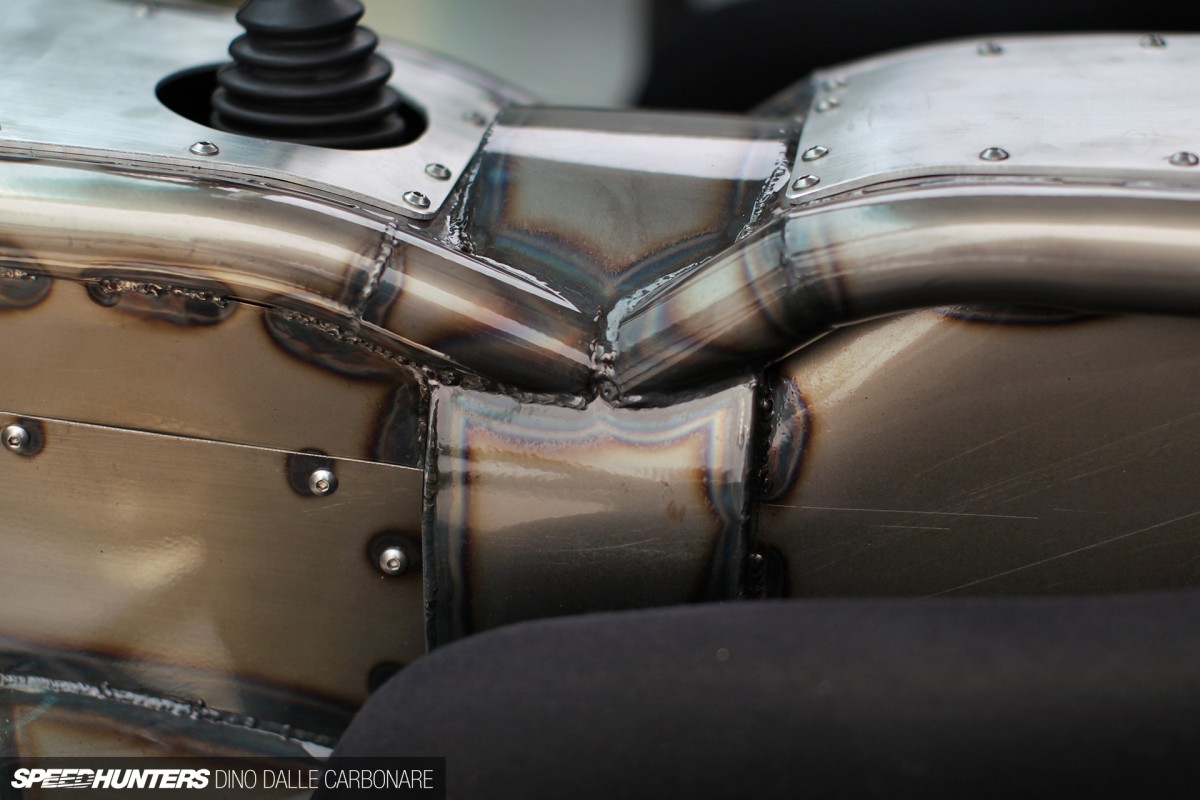

The exhaust exits the diffuser and is completed with dual 80mm alloy pointers, with the equivalent duration manifold and TD06 turbo…

… it equips the SR20 with that mid-mount rasp that may be at house on Meihan Sportsland circuit.

Pushed Via A Distinctive Taste

That is my meant experience peak. With a ground-to-floor clearance of 70mm throughout, it’s reasonably prime. There are low issues however those are all simply replaceable and can put on themselves in over the years. The Bridgestone Driftmaster wheels had been made in 2002; the frame taste is from a 2002 Hilux and all of it ties in with that theme. I grew up dreaming about flow vehicles from this period of Eastern drifting and I sought after to encase this in probably the most not going of frame alternatives. The entrance wheels are 17×8.5-inch and the rears are 18×9.5-inch, 0-offset all spherical.

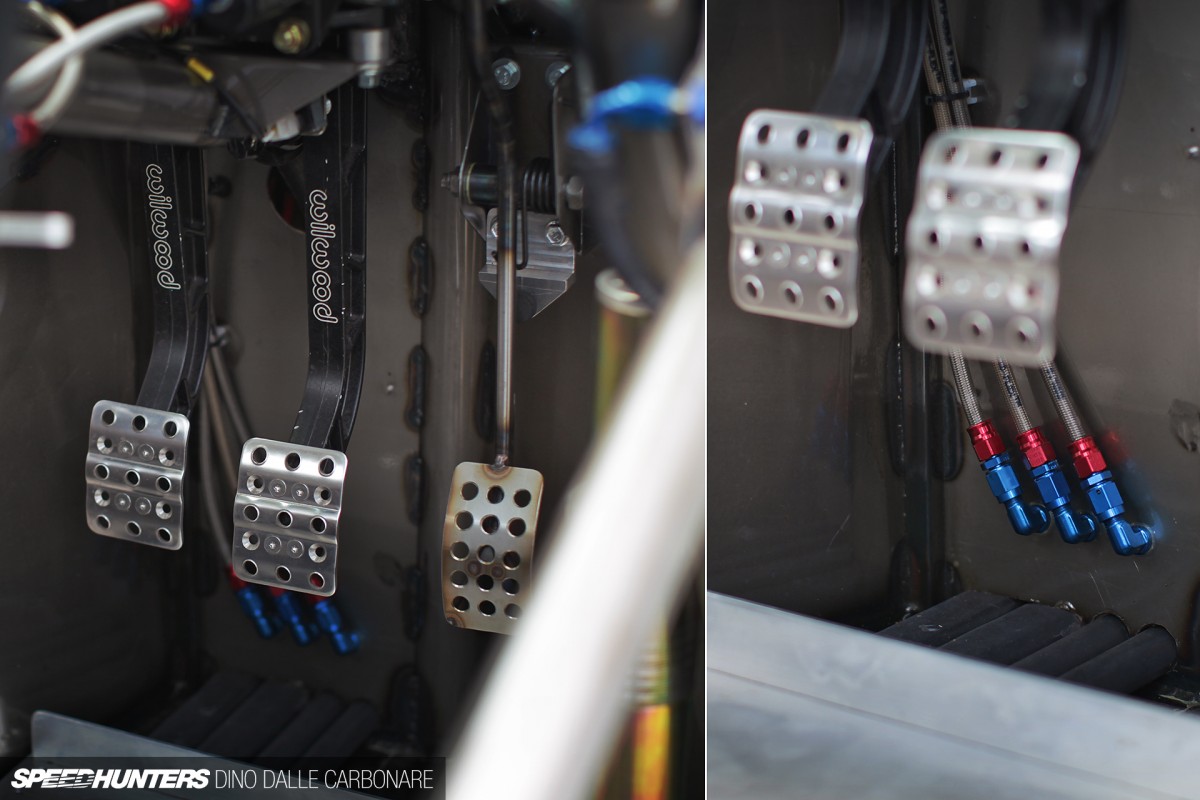

I run a 17/18 stagger on all my vehicles: I exploit 17-inch up entrance to get most guidance lock and guard clearance whilst the 18-inch rims within the rear succeed in most tuck. The brakes are a easy mixture of Wilwood pedal field, handbook rear lockout valve, Earls strains and Z32 callipers. In a light-weight automobile like this it’s plentiful braking energy on the cheap.

Issues are beautiful easy inside of…

… I sought after to go away as a lot of the chassis and the powder-coated end as visual as I may.

The RB25 gearbox that broke within the WTAC Tectaloy Float follow consultation is now out and shall be changed with a 6-speed sequential transmission.

Get right of entry to to the gearbox and exhaust is received in the course of the detachable sheet steel panels whilst the Racepak IQ3 sprint provides me with the entire knowledge and indicators from each the Smartwire and Hyperlink ECU.

A snappy have a look at the Wilwood pedal field and the braided hoses and Earl’s fittings that I laid out in the course of the firewall.

The seats are handiest brief as they’re out of my PS13. When finances allow I’ll substitute those with Bride Vios 3 Japan Version Kind R seats with upper thigh beef up.

There are minimum electronics within the cabin because of the easy unmarried cord Smartwire change panel dealing with all the controls.

The completed Hilux is a sight I may, and can, have a look at without end. It’s nearly understated at the outdoor and invitations you to seem below its pores and skin the place all is published.

SR20 Energy

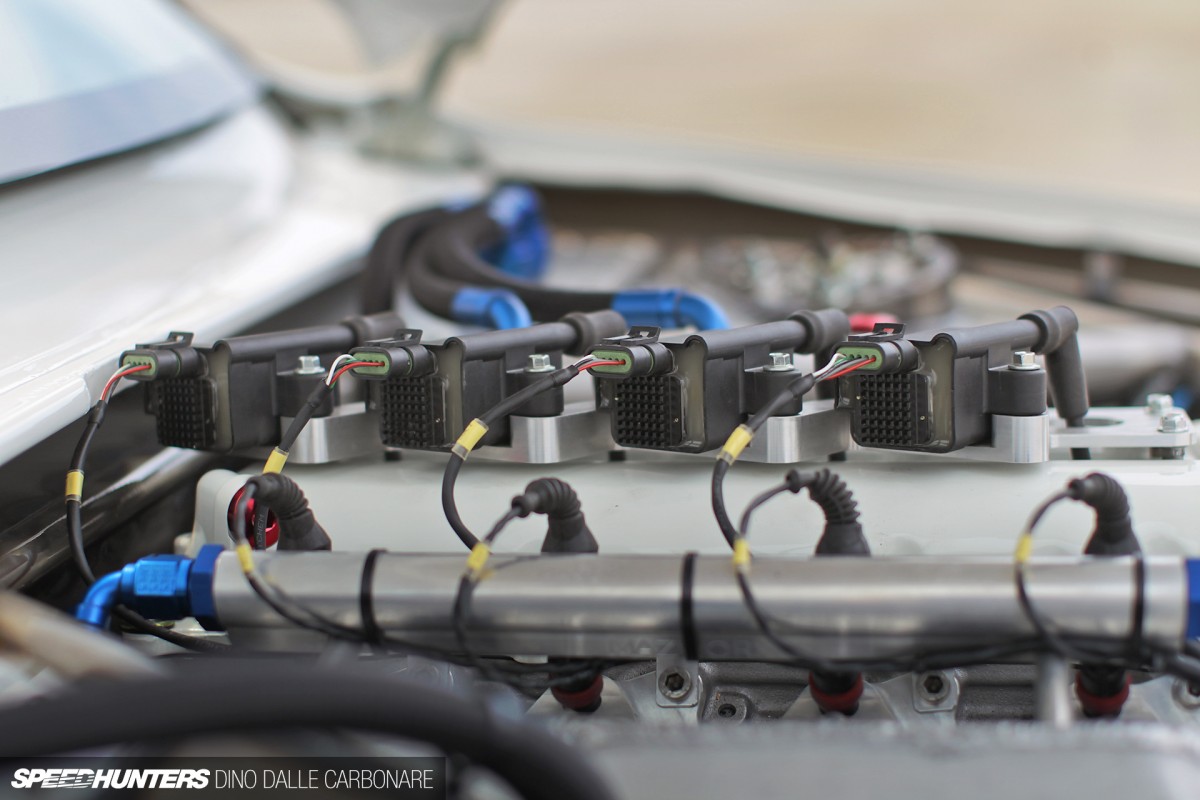

The engine is the SR20DET out of my PS13. It has a constructed backside finish with some upgraded cams and valve springs.

It wasn’t what used to be within the engine that I spent maximum of my time on, it used to be what used to be placing off it.

The recent aspect is an intricate mixture of portions to suit the chassis each bodily and aesthetically. My objective with the entire elements used to be for them to seem just right, paintings just right and be simple to carrier.

The one factor that wasn’t majorly changed used to be the lengthy motor itself. I remodeled the rocker quilt to feed the built-in oil catch tank…

… area the brand new coil mount and make allowance me to fill it with oil from a distinct place. The timing aspect of items used to be additionally upgraded, with a tradition cause wheel at the ATI balancer and a GT101 telling the Hyperlink ECU the engine velocity. The ECU could also be informed about cam reference with a tradition built in GT101 studying off the exhaust cam.

As you glance in the course of the engine bay and into the entrance suspension, you’ll understand tradition chromoly decrease regulate palms, caster palms and MCA uprights; it’s all bolted to the chassis by means of QA1 rose joints. The knuckles are S15 pieces I changed to optimise the guidance lock throughout the chassis. The entrance sway bar makes use of V8 Supercar blade adjustable ends and connects to the chassis by means of 1.5-inch chromoly tube and bronze bushings.

Just a little element of the entrance strut towers.

The cooling used to be left as much as PWR: the Queensland manufacturing unit took all my drawings and made me a tradition answer for air and water temperature regulate, all plumbed along side tradition stainless-steel piping.

I’d be mendacity if I stated I wasn’t in the slightest degree nervous about taking the Hilux out not off course with 30 of the arena’s easiest drifters on the Tectaloy tournament throughout the Global Time Assault Problem the opposite week. Lining up on the place to begin and staring down the straightaway, I tightened my belts and took a deep breath inside of my helmet. A daft quantity of hours over the last 2.5 years had come all the way down to this. I strung in combination about 8 laps earlier than coming in to switch to my RPS13. In the ones 8 laps I began to get an actual feeling for the best way the Hilux behaves. It’s not like the rest I’ve ever pushed, and the volume of mechanical really feel I won in the course of the guidance wheel used to be insane. You pay attention folks speak about a stiff chassis however you by no means totally perceive the have an effect on till you pressure one thing like this. It used to be a long way too short-lived even though and a few laps later, I sheared 3rd tools within the RB25 gearbox with an overly harsh unloaded over-rev that broke two rockers within the head. As I write this, I’m making plans on upgrading to a sequential canine engagement gearbox and getting again out not off course ASAP. This automobile used to be no longer constructed to compete or agree to the rest; it’s merely a imaginative and prescient that I sought after to transform a fact. Within the two and a part years from conception to final touch, I’ve learnt a fantastic quantity. I wouldn’t exchange a unmarried factor, however I might do issues so much in a different way if I had an opportunity.

I need to thank everybody for his or her beef up and I’m hoping that at some point they are able to see this within the flesh to get an actual really feel for the volume of middle and energy I poured into this construct. I will be able to’t wait to hide the entirety in molten rubber!

Nigel Petrie

Instagram: engineeredtoslide

Engineered to Slide

Pictures by means of Dino Dalle Carbonare

Instagram: dino_dalle_carbonare

dino@speedhunters.com

Engineered To Slide Toyota Hilux

Numbers: 900kg, 287rwkw (385whp), 22psi of spice up

Engine: Nissan S13 SR20DET, ARP head stud equipment, CP 86. mm solid pistons, 9.0:1 compression ratio, Eagle connecting rods, Tomei Powered rocker arm stoppers, Consider 264-deg/11.5mm consumption cam, Consider 272-deg/11.5mm exhaust cam, GReddy valve springs, HKS 1.2mm head gasket, Mazworx decrease CNC consumption runners with solid plenum welded on, 75mm Plazmaman throttle frame, GReddy TD06L2-20G turbo with tradition elbow at the compressor quilt, custom-built BRAE steam pipe manifold, Precision Turbo 46mm exterior wastegate, tradition 3-inch 304 stainless straight-through exhaust with dual 80mm alloy pointers, 35L spun alloy gas tank, Peterson gas clear out, Bosch 044 gas pump, Aeroflow Regulator, Ansu 1000 cc/min injectors, -8 Earl’s Prolite hose and Earl’s Autofit crimp hose ends, prime power coils, tradition 8mm spark plug leads, PWR customized radiator AN20 backside and AN16 best hoses, dual 10-inch thermo, lovers tradition alloy header/swirl pot, tradition alloy overflow tank., Hyperlink ECU G4 Hurricane, Autosport firewall mill-spec connector, tradition mill-spec labelled and concentrically twisted loom, MAC spice up solenoid, tradition shaved rocker quilt with dual AN10 breathers, tradition 3L catch can with exterior drain & clear out, Denso mini alternator with tradition pulley, ATI balancer, tradition GT101 corridor sensor studying a 24-tooth crank cause wheel, tradition GT101 corridor sensor studying the exhaust cam for reference, tradition alloy pulleys, tradition sensor plates, tradition engine mounts the use of rubber timber, built-in energy guidance reservoir into the chassis, inventory S13 energy guidance pump fixed the wrong way up on a billet mount

Driveline: Nissan RB25 5-speed gearbox, Z32 bell housing with tradition adapter, tradition shifter, Exedy Compe-D twin-plate take hold of, ATS carbon 2-way R200 diff with 4.1:1 gears, tradition one-piece propellor shaft, S13 part shafts rebuilt

Suspension/Brakes: MCA S13 entrance uprights, tradition MCA rear shocks, ex-FPR Racing V8 Supercar blade adjustable sway bar ends with tradition chromoly bars, tradition suspension palms constructed from chromoly and QA1 aluminium rose joints, reduce and close S15 knuckles to fit the facility & duration of the Hilux, Nissan Z32 callipers, DBA rotors, DBA pads, tradition hydraulic inline handbrake, Earl’s AN3 brake fittings and features

Wheels/Tyres: B.I.M Driftmasters 17×8.5-inch ET0 (entrance), 18×9.5-inch ET0 (rear), Federal 595 RS-R 215/40R17 (entrance), 225/40R18 (rear)

External: Customized-moulded rear FRP quarter panels, tradition FRP tailgate, manufacturing unit doorways, 3mm polycarbonate home windows, manufacturing unit metal cabin, inventory glass windscreen, tradition moulded entrance FRP fenders, FRP hood, inventory entrance bumper, inventory grille, Raybrig LED headlights, inventory 2002 Toyota Superwhite paint

Chassis/Internal: Delicate metal TIG-welded hand-constructed complete area body, Bride Vios 3 FRP seats, Nardi Vintage 330mm suede guidance wheel, Racepak IQ3 sprint, Racepak Smartwire with switch-panel

[ad_2]