[ad_1]

Every so often the most straightforward concepts are hiding in simple sight, in a position to make already quite easy engineering, like electrical automobile batteries, much more so.

‘Easy’ when compared with ICE, as it loses the complexity of the four-stroke engine’s fuelling and exhaust programs and increasingly more advanced emission-treatment paraphernalia.

And ‘quite’, as a result of even though EVs are routinely a lot more practical and haven’t any want for catalysts, advanced transmissions and even an exhaust, the science and electronics at the back of them is beautiful complicated stuff.

Stellantis not too long ago printed bold plans to part battery weight. The company has been taking part with battery producer Saft on a undertaking known as the Clever Battery Built-in Gadget (Ibis). It’s geared toward lowering the selection of an EV’s elements even additional via drawing near present electrical automobile battery generation in a moderately other manner.

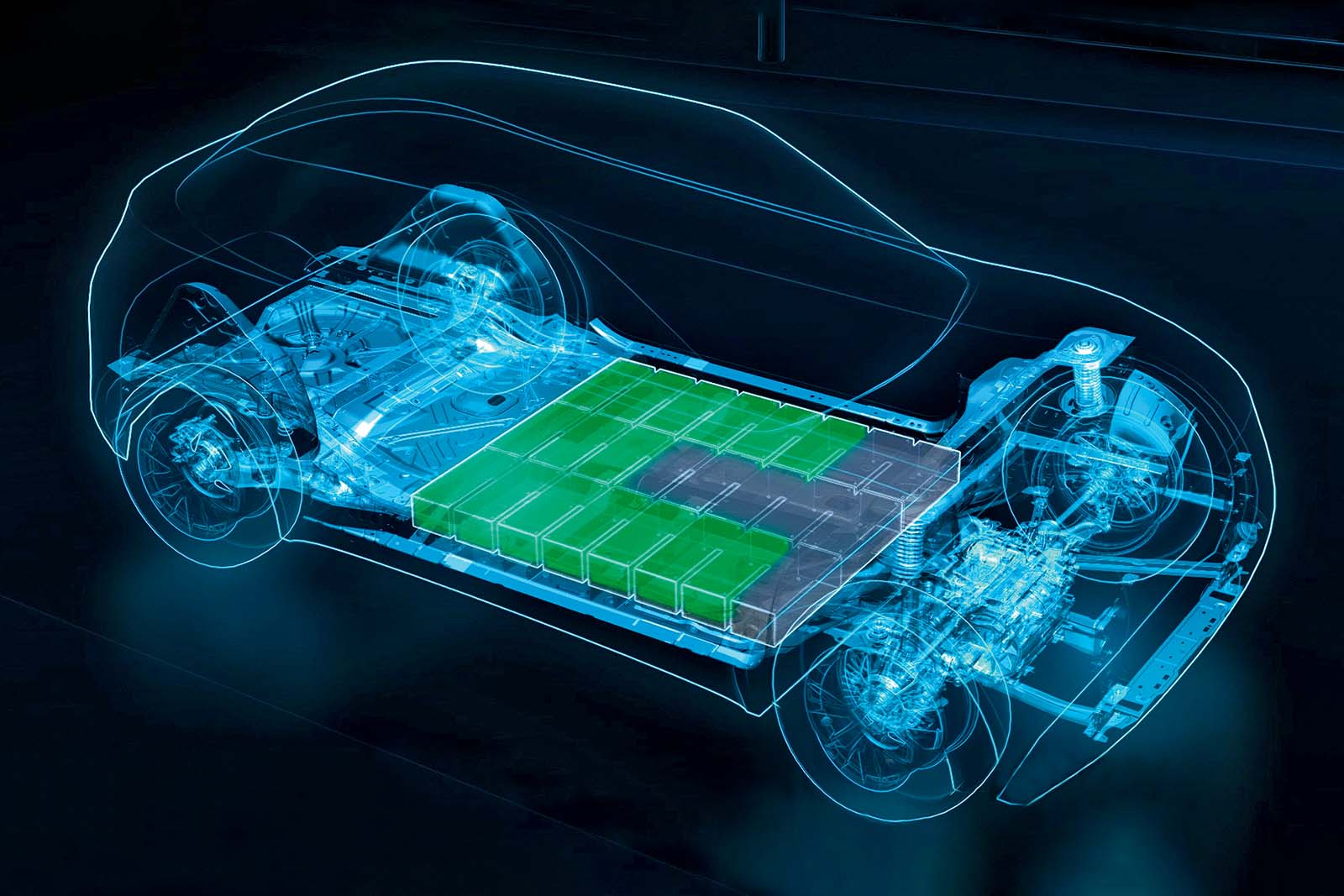

EV powertrains are usually made up of the similar construction blocks. There’s the battery, which shops and should be charged via direct present (DC) electrical energy. The electrical motors are powered via alternating present, like a family provide, so there’s an inverter in step with motor to transform AC to DC and vice versa.

The powertrain additionally has an on-board charger that takes the AC present from the grid and converts it to DC to feed the battery.

Electrical automobile batteries are extra correctly known as battery packs, as a result of they’re made up of infrequently loads of small, low-voltage, lithium ion cells. However quite than being all attached in combination within the pack, the cells are organized into modules. So whilst a battery would possibly generate 400V or 800V, the voltage of a person module could also be as little as 11V, relying at the pack’s dimension and design.

{Hardware}

The Ibis undertaking has taken a leaf out of photovoltaic programs to chop down the {hardware} in an EV. Solar energy technology programs include quite a lot of sun panels generating DC electrical energy, like a battery, which is fed to a unmarried inverter to transform to AC. Another is to make use of more than one microinverters changing the DC electrical energy to AC because it leaves every particular person panel.

The Ibis undertaking has taken a equivalent method. Each and every battery module has a microinverter embedded in it at the side of a charger, disposing of the will for an on-board charger and a high-voltage inverter (or inverters if there’s multiple pressure motor).

As an entire, all the battery pack produces AC present, now not DC, in a position for the motor. Stellantis reckons this method will get advantages small EVs, the place area is at a top rate. It’s additionally mentioned to be less expensive, most likely as a result of quite a lot of smaller charger and inverter electronics value not up to the high-voltage equivalents they’re changing.

Ibis is doubtlessly some other instance of leading edge pondering making improvements to the breed. On the identical time, it will now not turn out appropriate with different ideas, reminiscent of Volkswagen’s purpose to suit particular person cells without delay into the chassis of the automobile (‘Cell2Car’).

[ad_2]